How To Drill Long Straight Holes In Wood

How to Drill Directly and Square Holes without a Drill Press

Sure, every once in a while, you lot choose to intentionally drill a hole at a specific angle. Perhaps your compound joinery demands it, or you're going for a fashionable, contemporary look on a project.

But most of the holes we drill — I'd risk to say a good 99% of them — are intended to be drilled straight on, perfectly perpendicular to the surface. You tin do this precisely with a drill press, just many makers don't have ane, and they crave a specific setup and piece of work that's small enough to exist placed on the tabular array.

And then that leaves the cordless drill. A tool that, when counterbalanced on the tip of a drill bit, can exist easily canted and slanted off foursquare in every single management, specially when you're putting force behind information technology.

But! The task is non impossible. Yes, DIYers, you lot can drill a perfect xc° pigsty with a cordless drill. Here's how it'south done.

First, Ready Yourself Upwards for Success.

When y'all need to drill a perfect, 90° pigsty, yous need to business organization yourself with the angle of the drill and fleck and zip else. And then, to brand information technology easier, e'er brand sure y'all create a small-scale starting divot with an awl then your drill bit has a identify to land. This style, you bit placement is ready, and you can worry about the other moving parts.

The Commercial Option

The Milescraft DrillBlock is a elementary and super handy aid made for exactly this task. Information technology only costs $eight, and it helps you create perfectly square holes in one/sixteen″ increments from one/8 – 1/2″. It's a seriously skilful value, and if you use a cordless drill more a couple times a twelvemonth, it'due south a no brainer. Become one.

Yous just place it over your drill bit, gear up the fleck on your mark, secure it with your paw or a clench, and drill.

Bonus: the DrillBlock has a v-groove on the lesser, allowing you lot to drill 45° holes into corners and edges with ease.

Bonus: the DrillBlock has a v-groove on the lesser, allowing you lot to drill 45° holes into corners and edges with ease.

The DIY Option

Okay, but allow'southward say information technology's 10:00 p.m. on a Saturday, and you need to keep going with your project. Or, perhaps you lot need a hole that'due south not in increments of i/xvi″. Or any other of the dozen reasons you lot might need to drill a directly hole without the aid of the commercial guide. Well, then, my friend, you brand your own.

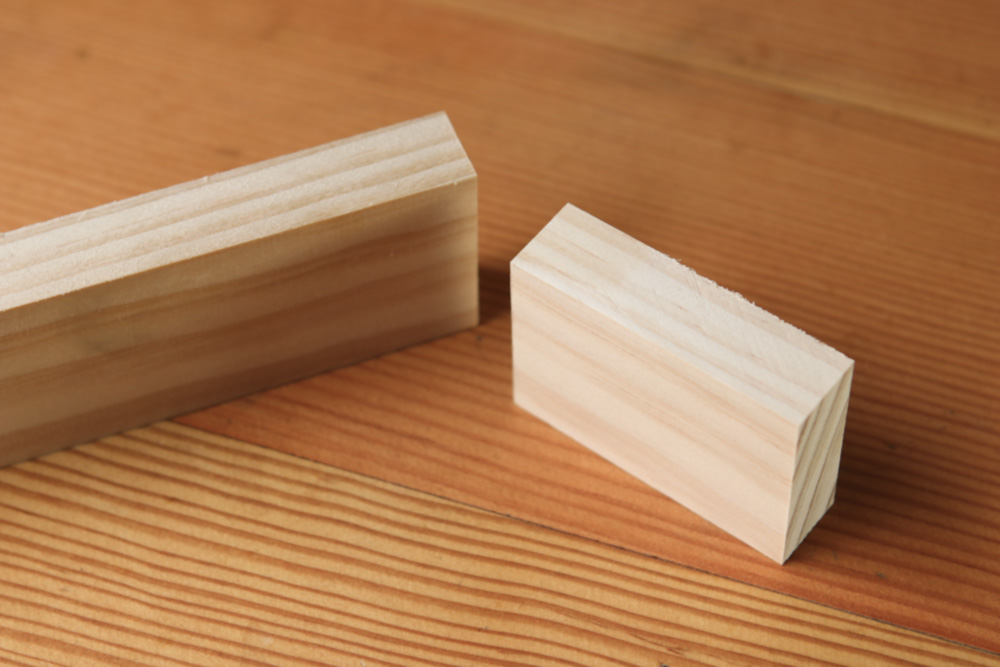

It's deceptively elementary. Start with some wood scrap, about 1 1/2″ wide and 10″ long. Cutting off 2″ from ane finish, ensuring the cut is perfectly square.

Spread a little wood glue on the cutting off, and so place information technology on the longer piece 1″ from the end. Utilise a square to make certain the two pieces are aligned.

Clamp the pieces together while the glue sets upward. (If you're in a hurry, you tin can fix the alignment with screws and get on with your project.)

Clamp the pieces together while the glue sets upward. (If you're in a hurry, you tin can fix the alignment with screws and get on with your project.)

To use it, simple line up the drill flake with the corner created by the guide. Employ your manus or a clamp to secure it to the work, line up, and go. Yous'll bore hundreds of spot-on holes of any size. Somewhen information technology'll vesture out, any you can just slap two pieces of scrap together and make some other one.

The Reusable Jig

If y'all need to drill a lot of hole of the aforementioned size, y'all tin modify the DIY jig for even more than consistency. Go to the brass and aluminum rod sections of the hardware shop or hobby shop, and await for a tube with an internal diameter than matches your drill bit. This won't be the number on the label, so accept your drill fleck or a pair of calipers with you to measure out. Cut a ane one/two″-ish piece off the end.

And then, use some hot cook glue to secure it to one of the sides of your drill guide. You've essentially made a collet to guide the fleck, which uses the same principle at the DrillBlock above.

Now… let's check our piece of work.

Nailed information technology!

Nailed information technology!

Source: https://www.manmadediy.com/4692-how-to-drill-straight-and-square-holes-without-a-drill-press/

Posted by: stoverhoatherand.blogspot.com

0 Response to "How To Drill Long Straight Holes In Wood"

Post a Comment